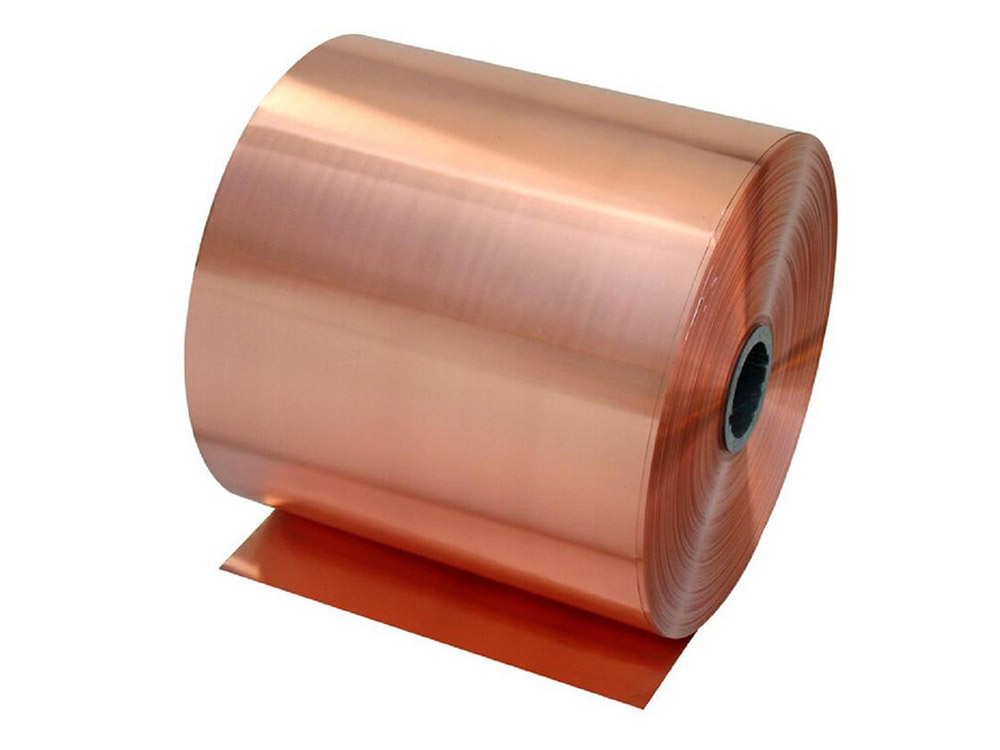

Copper foil is a thin sheet of copper with a thickness typically less than 0.2 mm. It is flexible and can be easily manipulated

Our Copper Foils are known for their high quality, perfect shape, smooth surface, and excellent mechanical properties. We carefully monitor various factors to ensure that these foils meet the highest standards, making them ideal for many uses.

What is Copper Foil?

Copper foil is a thin sheet of copper, usually rolled or electro-deposited, that can range from micrometers to millimeters in thickness. Because copper is highly conductive and flexible, copper foil is widely used in electronics, energy storage, and industrial applications.